PACKAGING SERVICES

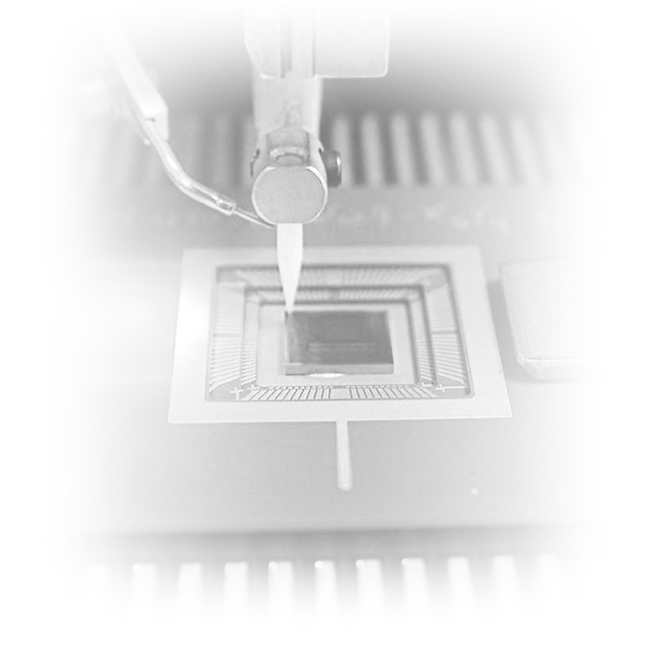

Precision Wire Bonding and Die Bonding

American Dicing has 30+ years of experience with die bonding, wire bonding, and packaging.

Die Bonding

Die bonding, also known as die mounting, is the attachment of a die (or chip) to a substrate using an epoxy—conductive, non-conductive, or solder.

American Dicing uses automated die mounting machines with the following capabilities:

Multi-Chip

Die Attach

Flip Chip

Accuracy of 10µm

Dies sizes of 0.008” and Up

Wafer size up to 12”

Waffle pack, Gel-Pak®, and feeders

Wire bonding

Wire bonding is the process of creating the vital interconnection between components of the device to enable the reliable transfer of electrical signals.

American Dicing has several wire bonding options that meet your needs. We offer ball bonding, wedge bonding, and heavy ribbon wedge bonding using gold, aluminum, or copper wires.

Ball Bonding

Ball bonding is a commonly used technic where a ball is placed on each bonding pad with a wire connecting them. Ball bonds are multidirectional.

Our ball bonding machines can use wires ranging from 17.5 to 50 µm. The machines have a resolution of .25 µm and repeatability of < 2 µm.

Wedge Bonding

Wedge bonding is a unidirectional process that enables the bonding of pads that are closer together (fine pitch) and can have lower/shorter loop heights. The process can also use ribbons.

For our standard wedge bonding, we can use gold or aluminum wires from 17.5 to 75µm in size or a ribbon size of 30 µm x 12.5 µm to 250 µm x 25 µm

Additionally, we offer heavy ribbon-wedge bonding that uses aluminum ribbon sized from 500 µm x 75 µm up to 2000 µm x 300µm or copper wire from 300 to 500 µm.

Wire Bonding Material

We use gold (Au) or aluminum (Al) for most customers needing wire bonding. We also have experience with copper. Each material has advantages/disadvantages, as shown in the table. Please reach out to discuss which material is best for your needs.

GOLD (Au)

Advantage

Good electrical conductivity

High thermal conductivity

Disadvantage

Higher cost

SPECIFICATIONS

0.0007” to 0.003”

ALUMINUM (Ai)

Advantage

Lightweight

Cost Effective

Disadvantage

Lower thermal conductivity

SPECIFICATIONS

0.0007” to 0.025”

COPPER (Cu)

Advantage

Excellent thermal / electrical conductivity

Cost Effective

Disadvantage

Material can oxidize without protection

Packaging

Wire Bonding Evaluation

After assembly, we have wire pull and ball shear testing to ensure the wire bonding is successful.

Inspection

Before final packaging, our QA team inspects all wire bonding to confirm proper assembly. Our team can provide Inspection reports as required.

Encapsulation

Encapsulation protects the bare wires from damage or breakage from physical or environmental stress.Encapsulation services are provided with a glob top or epoxy seal. Glob top seal can be one-part/two-part or UV-curing, depending upon your needs.

Battery Bonding

We have expanded our wire bonding to battery capabilities in response to the industry’s increasing need for multi-battery cells.

We offer tab bonding. Unlike ab and laser welding, tab bonding uses a cold process that helps reduce battery degradation. Tab bonding can be used to connect serial battery cells or to connect the battery cells to other components.

Battery Schematics

Specifications

Die Mount

Goldball Bond or Wedge Bond

Goldball bonding (0.0007” to 0.003” wire)

Aluminum wedge bonding (0.0007” to 0.025”)

Glob top or epoxy seal

Die Sizes From .008" and up

Wire pull and ball shear test

Die placement accuracy within +/- .001" on all die

Machines

Datacon 2200 Evo.

F&S Bontec Wirebonders

Nordson EFD Epoxy Dispensers

ASM Eagle Extreme

SEC 3088

K&S 1488