Die Sorting Services

Pick, Place, and Sort into Tape Reel or Waffle Pack

Wafer dicing is the precise separation of individual die (chips or integrated circuits) from a semiconductor wafer. At American Dicing, we have expanded our dicing from semiconductor wafers to many other materials, including glass, sapphire, quartz, graphene, and ceramic. The list of materials we work with constantly expands as we develop new processes.

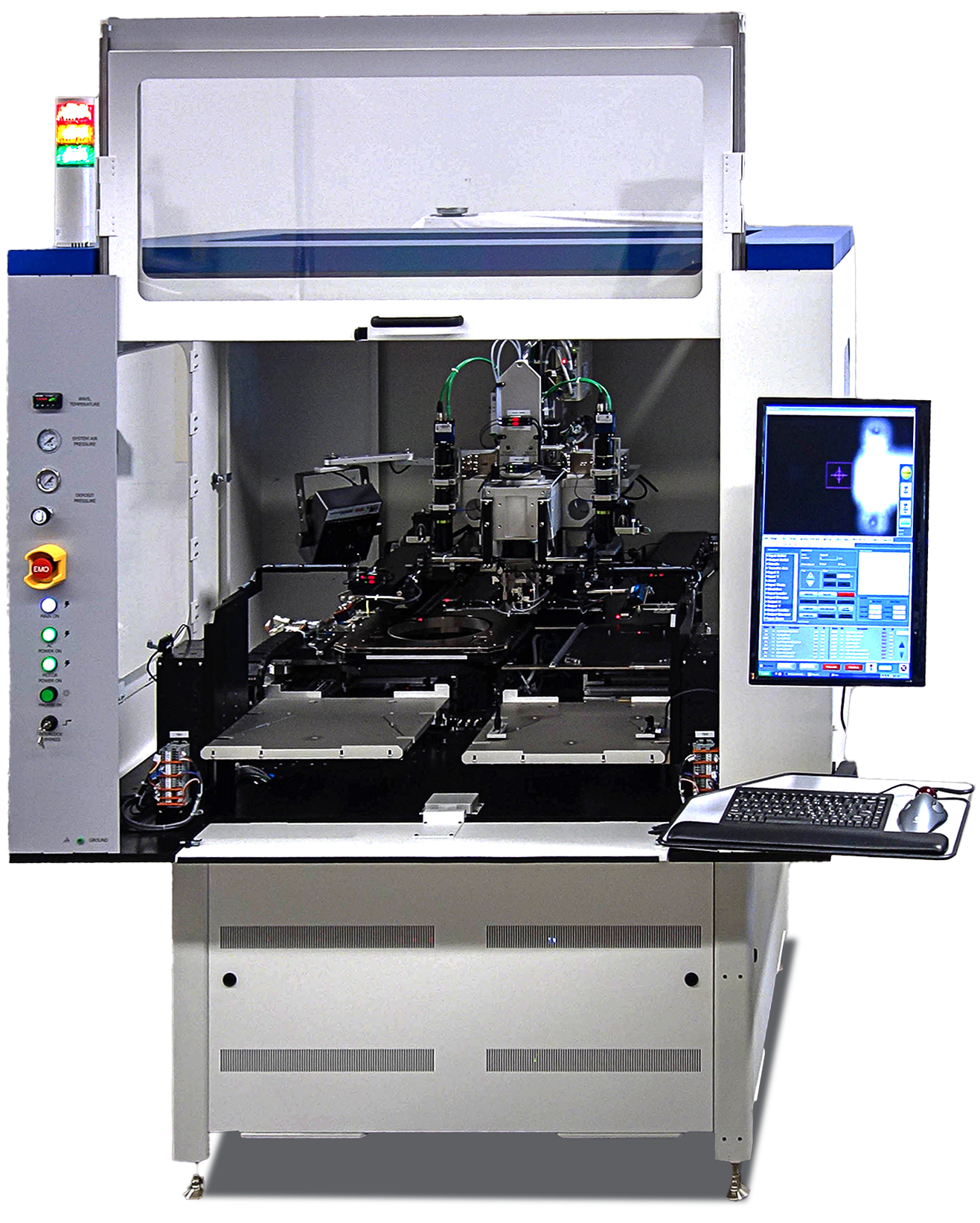

Our fully Automatic Die Sorters include wafer mapping and vision inspection before picking and place into a variety of outputs.

Die Sorting Process

Die Inspection before Pick

Our machines use visual inspection tools to automatically separate good dies from bad ones, including edge defect inspection and ink dot removal.

Wafer Mapping

Additionally, we can use provided electronic wafer maps to sort predetermined good/bad dies.

Multi Die Binning

We have multi-die binning capabilities to separate dies according to your specificities.

Input Options

We can transfer die from tape, frames, hoops, tape and reel, or waffle packs to new desired outputs.

Traceabilty

We can maintain traceability of the die throughout the process on request.

Pick & Place Applications Setup

Multiple needle/collet configurations can be used to optimize sorting.

Die Inspection after Placement

Following sorting, the dies are inspected to ensure no damage occurs during picking/dicing

Lot Size

Small or large production job capabilities are available.

Wafer Size

Capabilities range from a small sample size to 12” Wafer capabilities.

Product Labeling

Once dies are sorted, we provide custom labeling, including bar or QR codes if desired.

Packaging before Shipment

Waffle Packs and Jedec trays can be vacuum-sealed for long-term storage.

Die Sorting Outputs

Depending on your requirements, wafers are sorted into various outputs.

Waffle-Paks • Gel-Paks® • Jedec Trays

Frames Tape and Reel • Grip-Ring hoops

Specifications

Die sort into waffle packs, tape & reel, Gel-Paks, Jedec trays, or film-frame

Die sizes from .008" and up

Up to 12" Wafer diameter Capability

Ink dot or wafer map input

Flip Chip capability for bumped devices

Die sorting from wafers to new wafers with known good die

Manual pick and place for pressure sensitive parts

Vacuum seal dry packaging

Customized labeling

Waffle Paks

Advantage

Small and thin, can get custom sizing for irregular shapes

Easy to handle

ESD and non ESD types available

Disadvantage

Typically single use only

If proper pack isn’t chosen die can rotate/flip

Lacks features to facilitate automation and large scale processes

Die Size Capability

0.008” and up

Gel-Paks®

Advantage

Die held by surface tension, prevent damage from edges/top of carrier

Smaller die are easily adhered to Gel Material preventing loss and movement during shipment

Disadvantage

Higher Cost

Slightly more difficult die removal due to adhesion to Gel

Lacks features to facilitate automation and large scale processes

Die Size Capability

< 10 mils – Gel-Pak Specific

Jedec Trays

Advantage

Strong, stackable trays

Custom sized to grip die and minimize movement

Accommodate most standard components including BGA, CSP, QFP, TQFP, QFN, TSOP and SOIC

Disadvantage

Larger minimum order quantities, larger sized die specific

Die Size Capability

3 mm and up

Tape & Reel

Advantage

More common in large scale production, used in automated machines

Compact packaging, parts are sealed to protect from damage/dust during storage

Disadvantage

Not preferred with smaller die due to pocket tape limitations

Die Size Capability

~ 4 mm and up

Frames & Grip Ring Hoops

Advantage

Layout can be customized to suit your needs

Good die can be repopulated on tape removing all bad die

Disadvantage

Can be difficult to remove die from tape

Not optimal for long term storage as tape properties change over time

Die Size Capability

~ 0.008” and up

Die Sorters

DS4000

DS7000

DTS2 Pick & Place

ESC Magnum